Standard Sheds

£760.00 – £3,374.99 Including VAT.

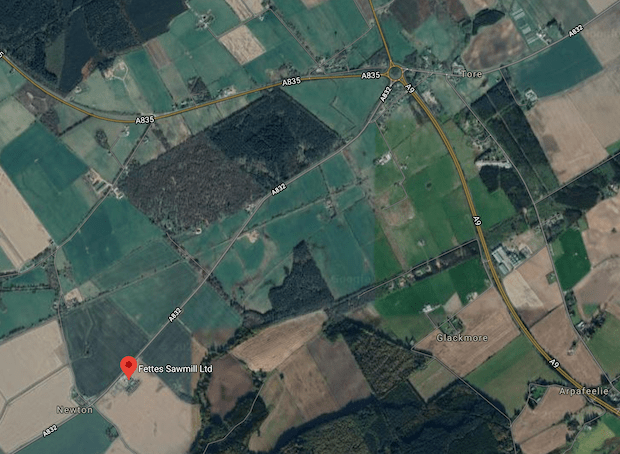

Fettes sheds are made to order. We have a range of display models on site so you can see our high quality for yourself.

Local Delivery and Installation, available at an additional cost. Base must be in place prior to installation. Contact us for more details.

Fettes sheds are made from Pressure Treated Timber this protects from Rot and Insect Infestation. It does not make the wood waterproof.

All product photographs and images are for illustration purpose only and may differ in colour and style. Timber is a natural product which is affected by temperature and moisture, it can expand, fade, warp, crack or split. This will not diminish the overall quality of the products supplied and is not a default in manufacturing processes.

All Fettes Sheds are made to order. Production Time Approximately 4-5 Weeks. Lead times are subject to change.

Local Delivery and Installation are available contact us for more information.

We do not do any Base works, for sheds we recommend either a level Concrete pad or slabs the size of the base timbers.

Contact us for more information:

Tel: 01463 871222

Email: sales@fettessawmill.co.uk

Click Below for our contact form:

Standard Sheds

Our single or double door wooden sheds are perfect for those wanting easy storage for garden tools, equipment & vehicles (size dependant), these sheds can also be used as a great workshop. Windows can also be installed.

Standard Sheds by FETTES

At FETTES we make our Standard Sheds to order, using 20mm LOGLAP as standard. Our Green Pressure Treated, quality LOGLAP is bought from carefully selected sawmills around the UK. Every step from the sustainable forest to your garden must meet strict rules that are audited by various independent inspectors. Our LOGLAP construction sheds features tongue and groove boards which interlock to form a tough, weathertight finish which will deter warping. The LOGLAP scallop design we use creates an attractive finish which aids with water run-off. The LOGLAP has been pressure treated with eco-friendly preservative to protect them from insect attack and rot. The internal floor and supports are also pressure treated to aid a longer life. Our polyester reinforced tear resistant Roofing material (Super Shed Felt) is used on all our made to order sheds. This is polyester tear resistant material which provides a high performance, with a green mineral finish. All our large sheds have a modular design for aid of transportation and installation. Benefits of modular panels as they have more internal framework than in standard sheds, resulting in a much stronger built shed. The modular design also means the panels are less prone to warping. Joins in the modular construction are protected by outer weather covering strips to prevent any water ingress.

All our sheds are made in Metric sizes (approximately) by our experienced staff. Taking great pride in their work, which is seen in every building we manufacture and produce, whether large or small we undertake to supply the highest quality.

Our premium Standard shed is also available in nine various sizes, from 1.8m x 1.2m to the large 4.8m x 3.6m.

Additional doors and windows can be added if required however, security of the building may become a problem, so keep this in mind when ordering.

Common Usage:

- Tool Storage

- Workshops

- Storing garden items and furniture

Notice: Customers are advised that although our own buildings are Pressure Treated against rot and infestation, this DOES NOT make the building waterproof, and a recognised product must be used to waterproof the building.

Delivery and installation services are available LOCALLY only at an additional cost. Shed foundations are not included in this cost (i.e. concrete base, slab etc.). The base can must be arranged if required, prior to the installation. Fettes do not carry out any base works, for installation a flat level base is required to support the whole building.

Call our friendly sales staff on +44 (0)1463 871222 for details and cost on all sheds, delivery and installation availability in your area.

Additional timber protection advised, See terms and conditions on the page header before submitting your order.

| Dimensions | N/A |

|---|---|

| Unit Size | 1.8m x 1.2m, 2.1m x 1.5m, 2.4m x 1.8m, 3.0m x 1.8m, 3.0m x 2.4m, 3.6m x 2.4m, 4.8m x 2.4m, 4.8m x 3.0m , 4.8m x 3.6m |

| Door Type: | Single, Double |

| Window: | No Window, Perspex Window |

| Roof Covering Type: | Felt Roof |

| Roof Style | Apex, Pent |

FETTES Wood Products

Please Note: Timber is a living product and will eventually need replacing. Although the wood preservative used in the pressure-treatment process is of the highest quality eco-friendly preservative to protect timber from insect attack and rot, it doesn’t protect timber from the effects of weather. UV light is responsible for most damage to exposed wood because it changes or destroys the wood’s lignin, a component of wood that hardens and strengthens the cell walls. In more scientific terms this process is called photo-oxidation. Without additional protection UV rays from the sun will weather timber changing the colour to silvery grey. It is also recommended to keep all vegetation at least 24 inches away from wood surfaces to allow for adequate ventilation and drying out of these surfaces when wet. Moisture will negatively affect the lifespan and performance of a timber product, so it’s essential to add a high-quality protective water-repellent coating to our product to get the best possible life span. This is best undertaken with a solvent-based treatment during the summer months, so that it can soak into the dry wood. Clean the wood surfaces to remove all foreign materials from the wood prior to the application of an exterior finish system. The overall performance of even the best finish system is dependent upon proper surface preparation and application technique. A wide range of wood treatment products are available on request and at our showroom. The timber colour may vary dependant on the timber and chemical protection used.

See terms and conditions on the page header before submitting your order.

Call our friendly sales staff on +44 (0)1463 871222 for details and availability.